PORTFOLIO OF OUR PROJECTS

For our clients we usually provide services such as:

- Stocktaking of existing facilities, equipment and installations,

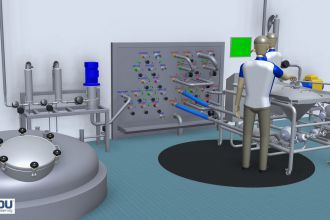

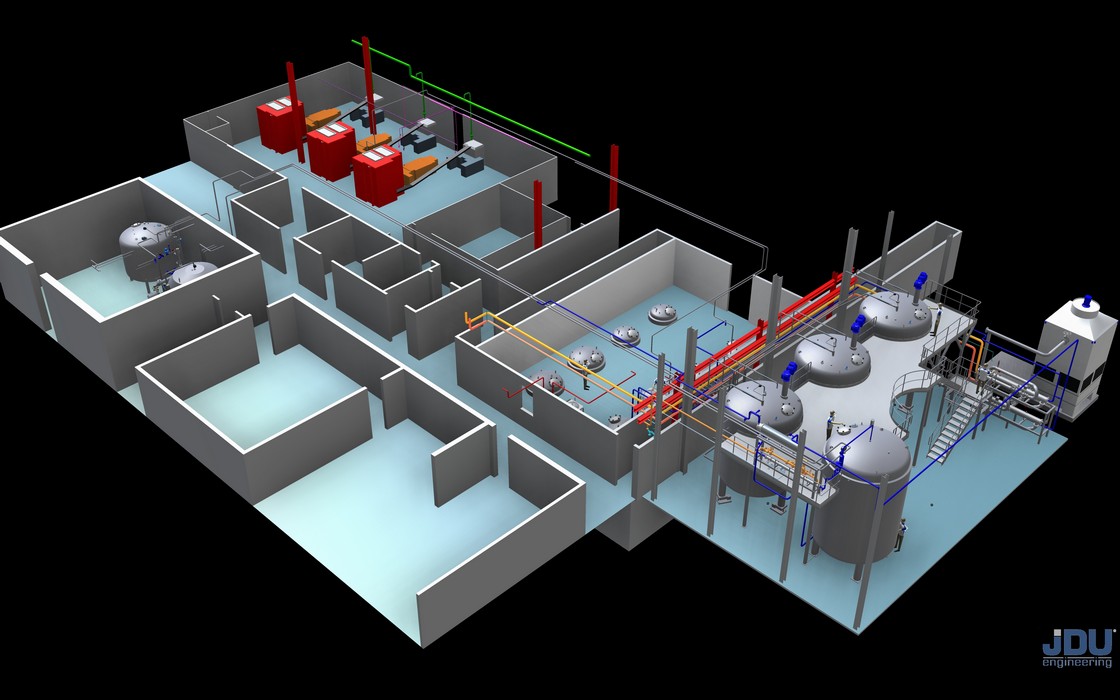

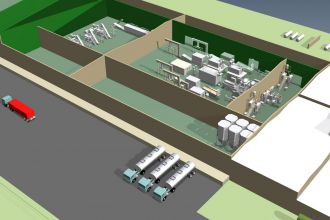

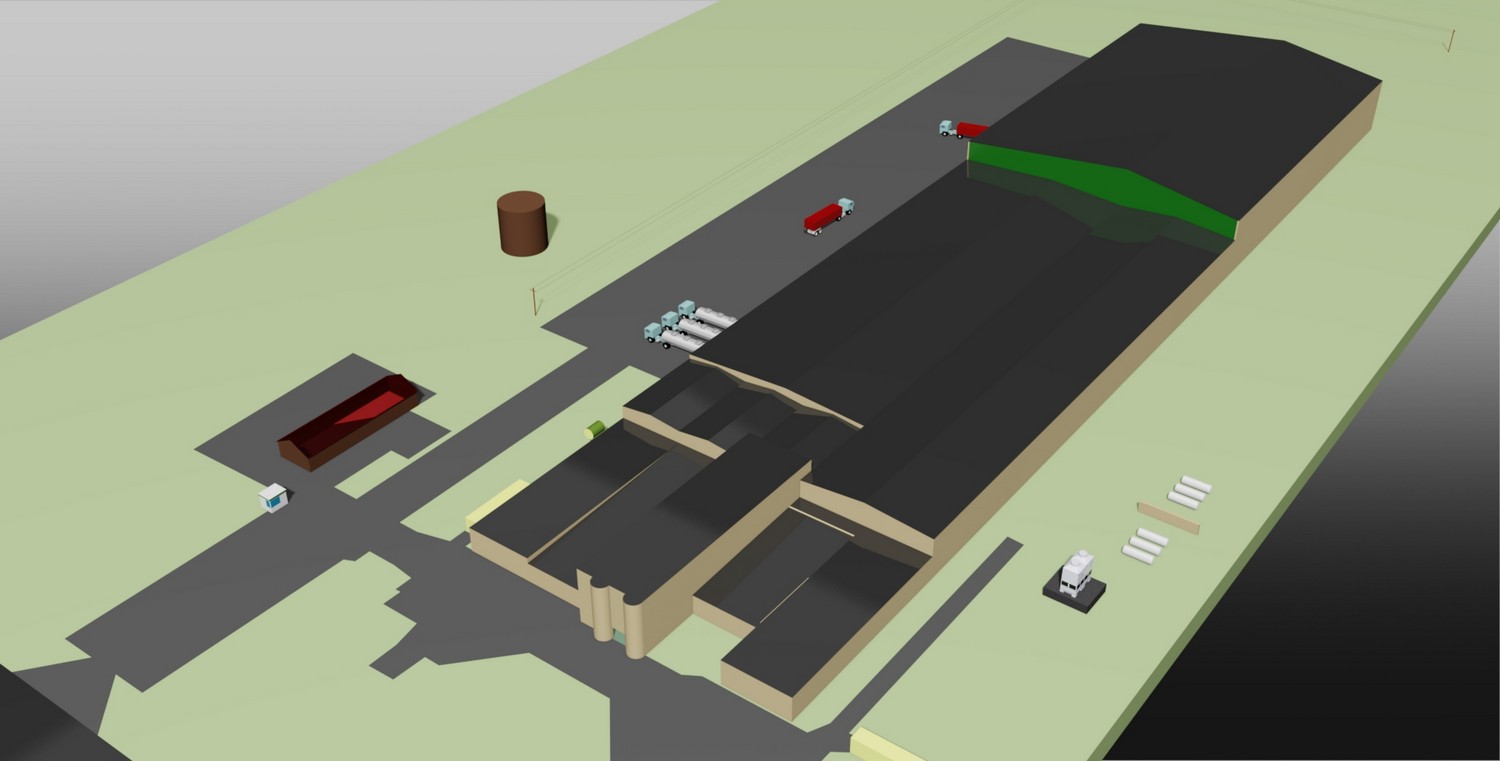

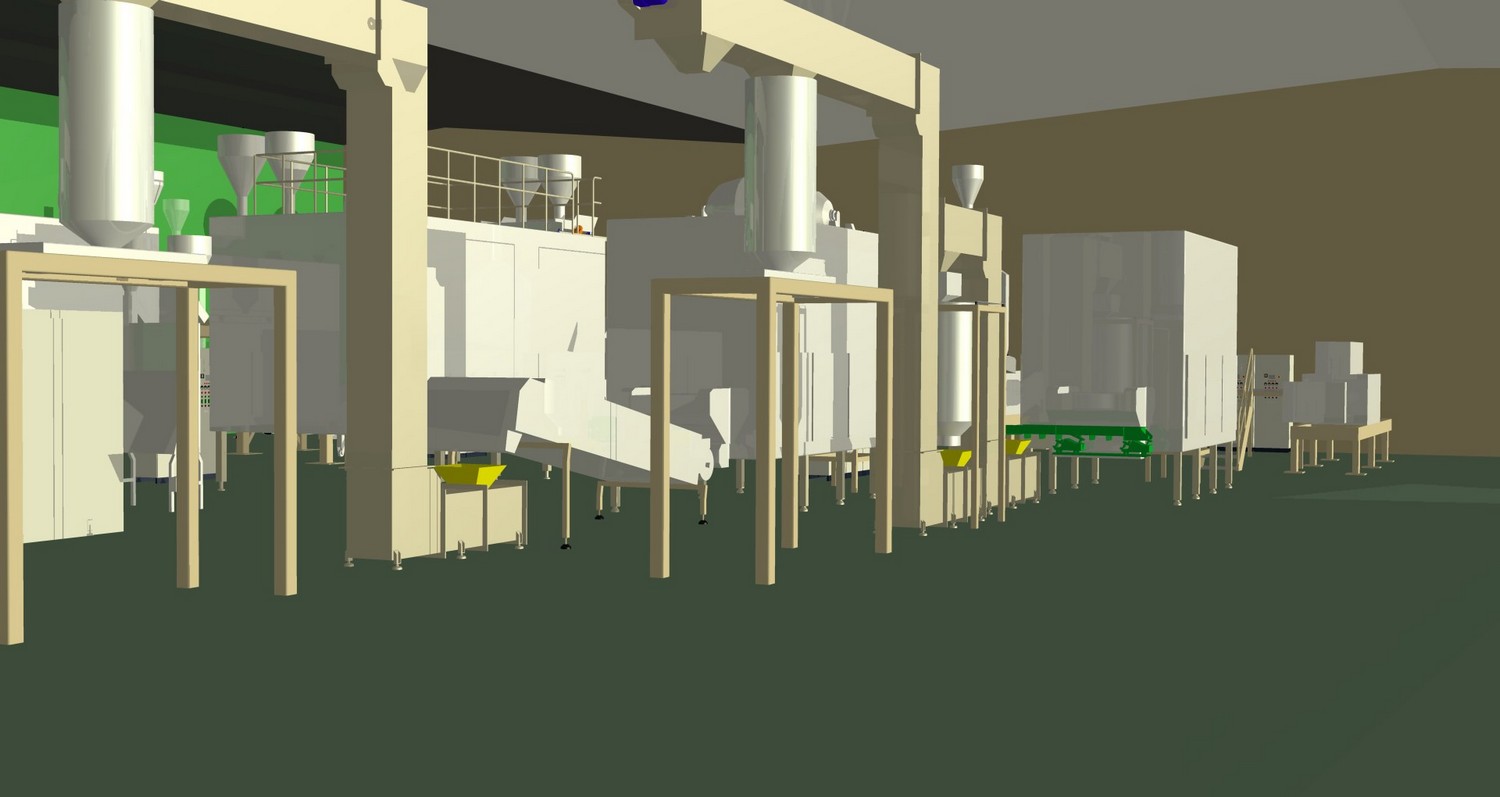

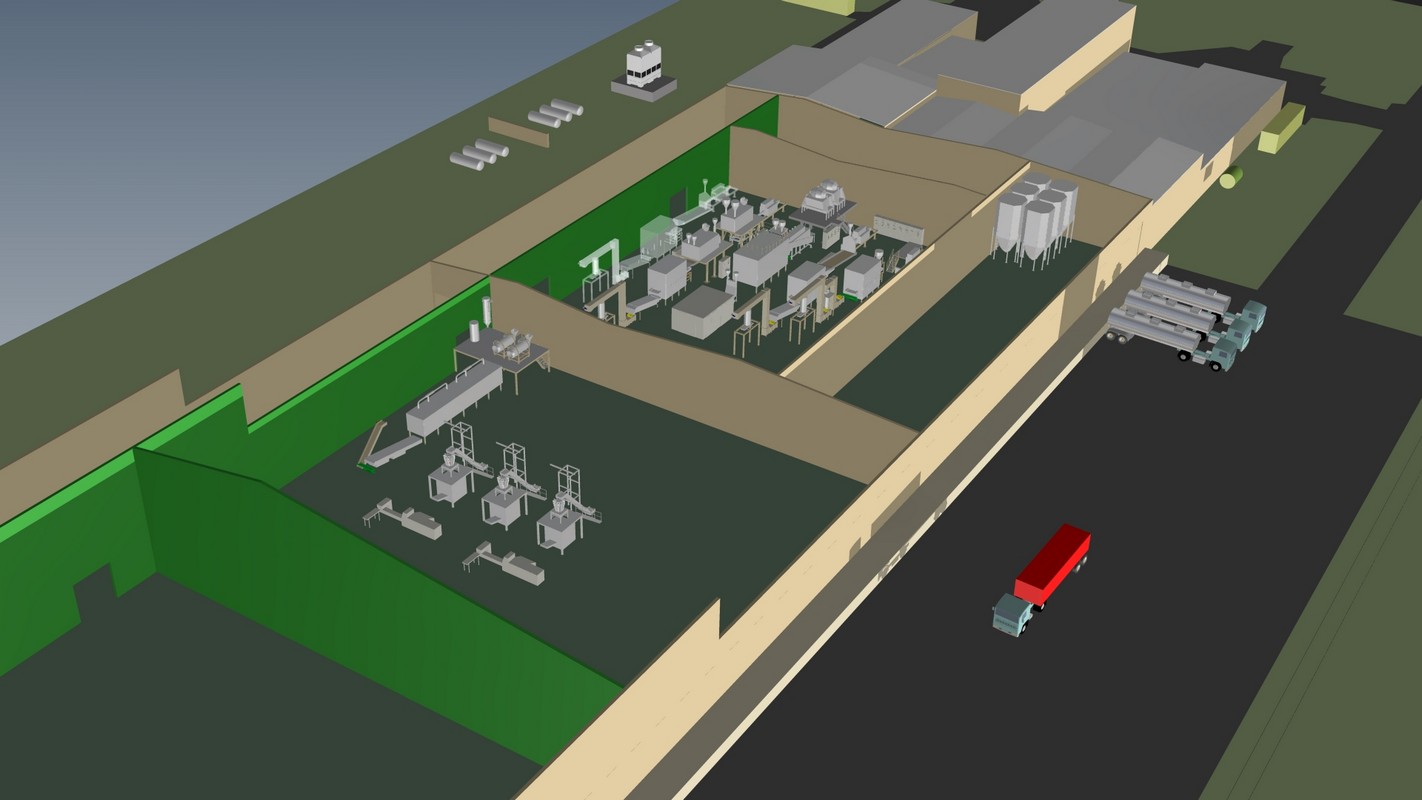

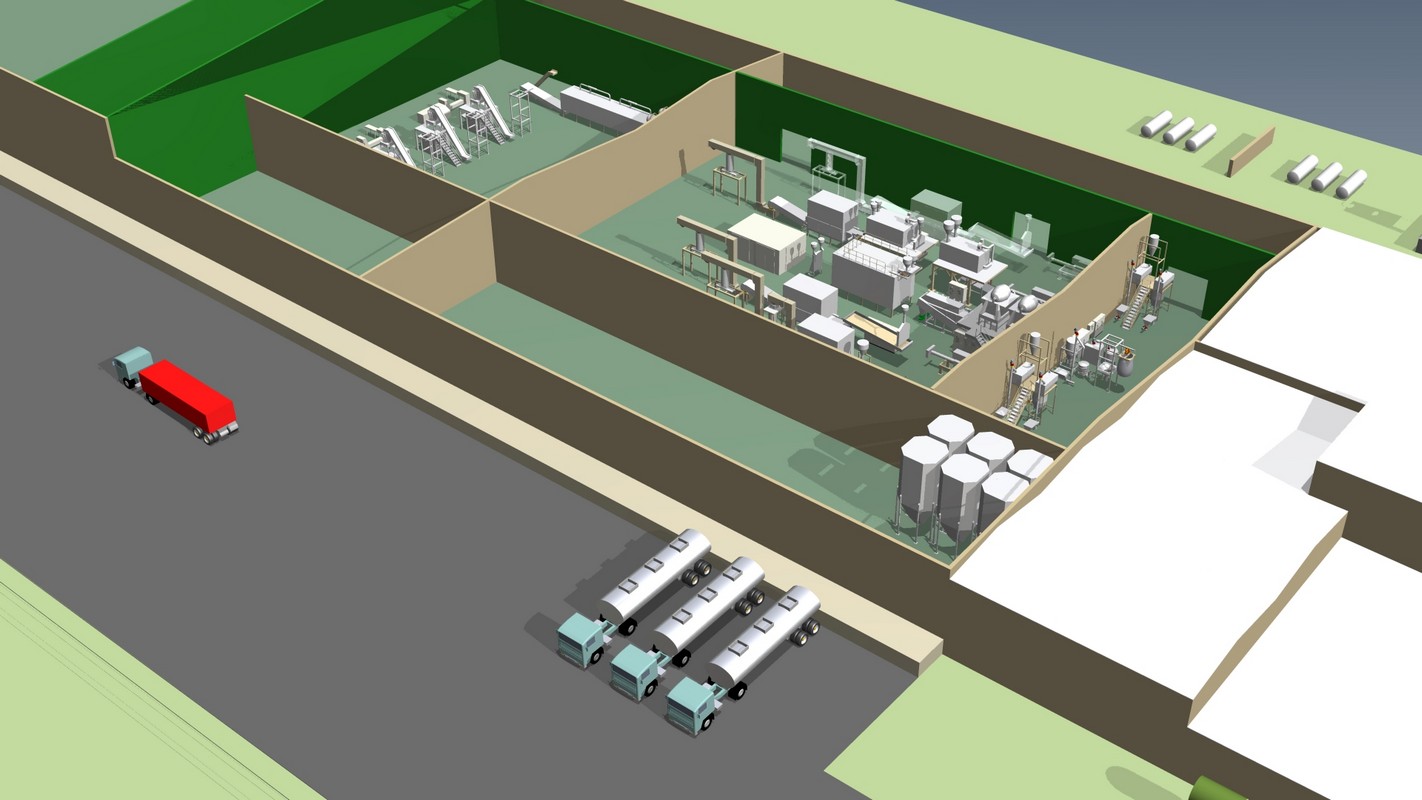

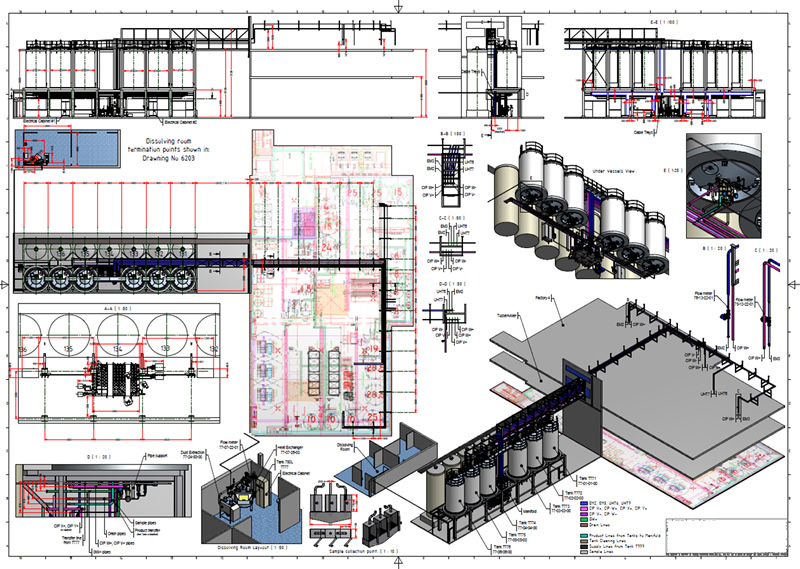

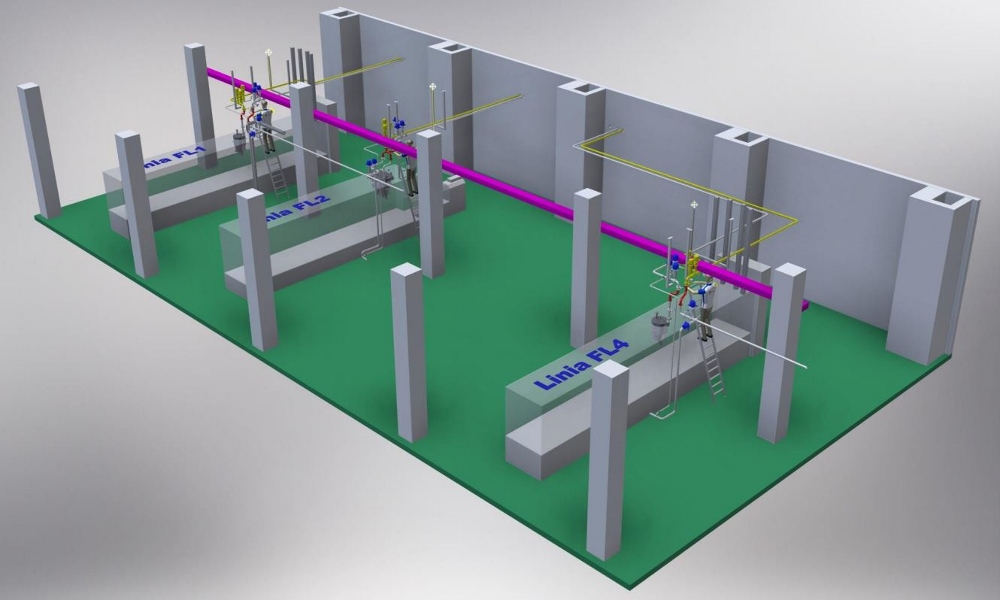

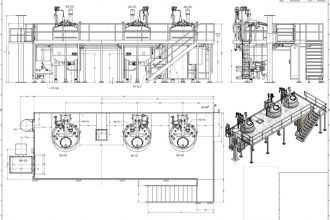

- Preliminary projects, concepts - for reviewing the proposed technical solutions,

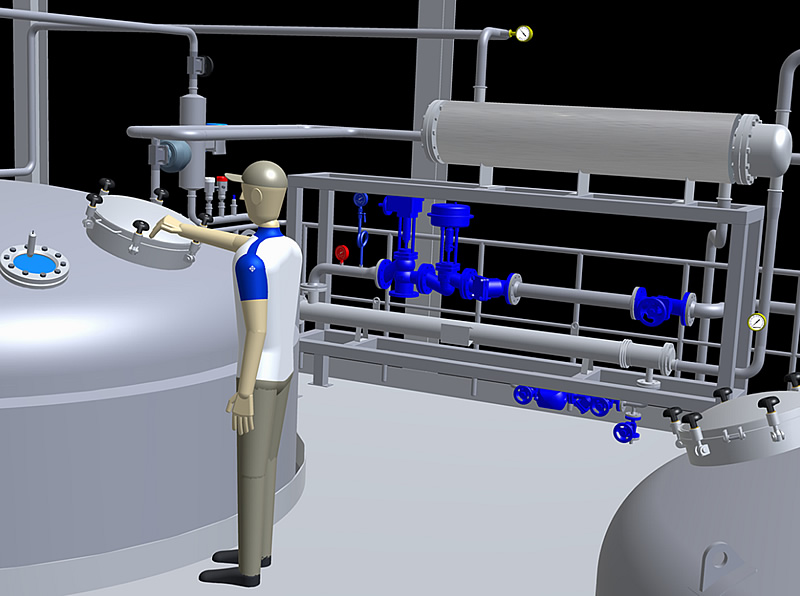

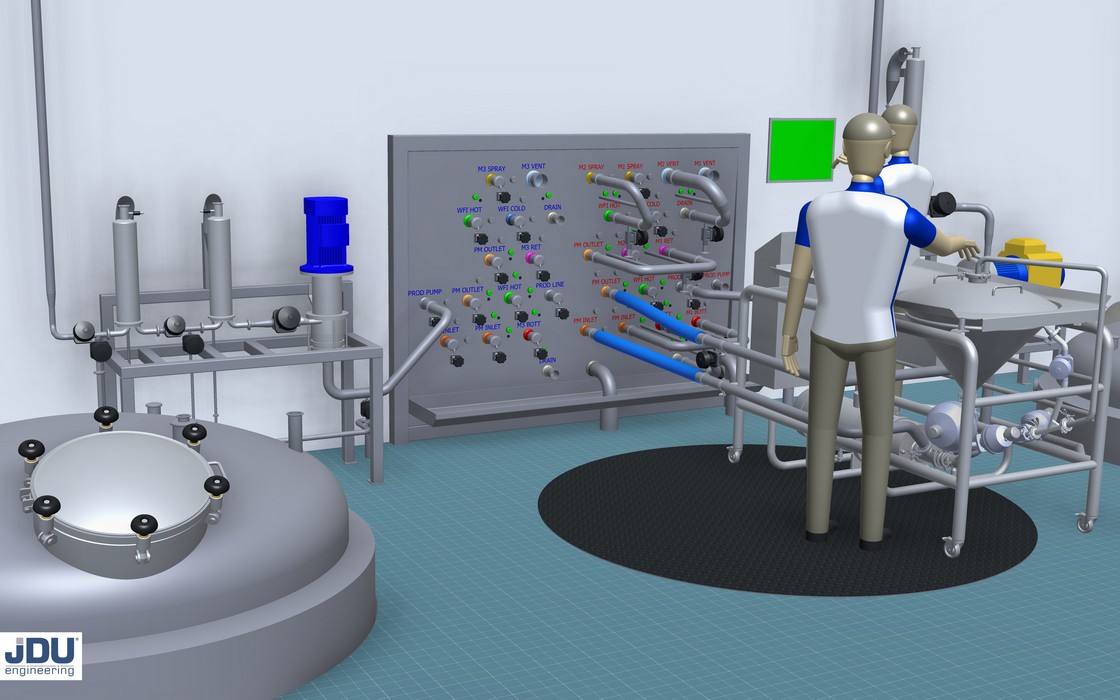

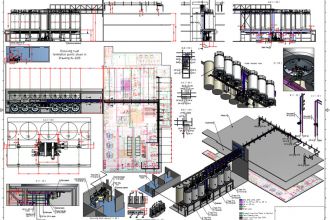

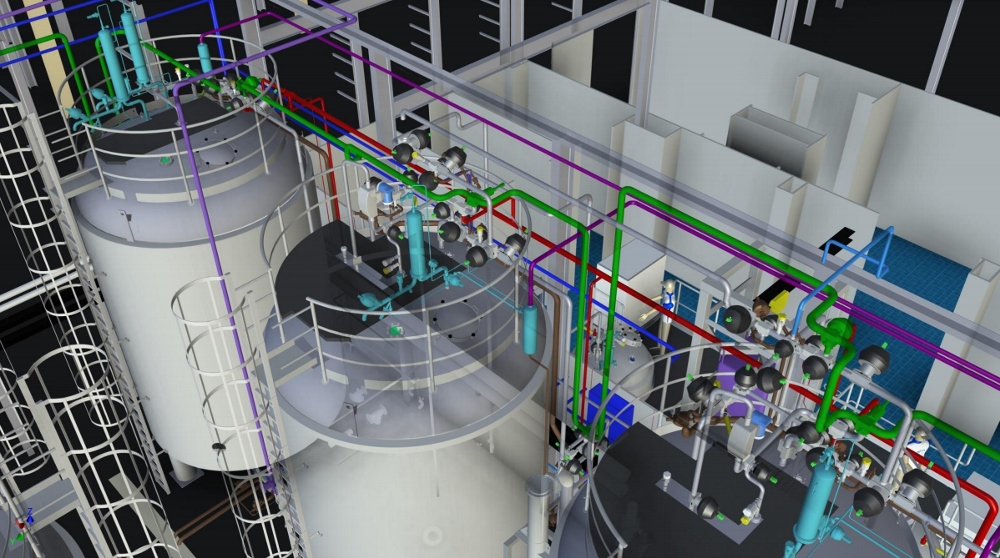

- Development of P&ID diagrams for installations, specifications of equipment lists,

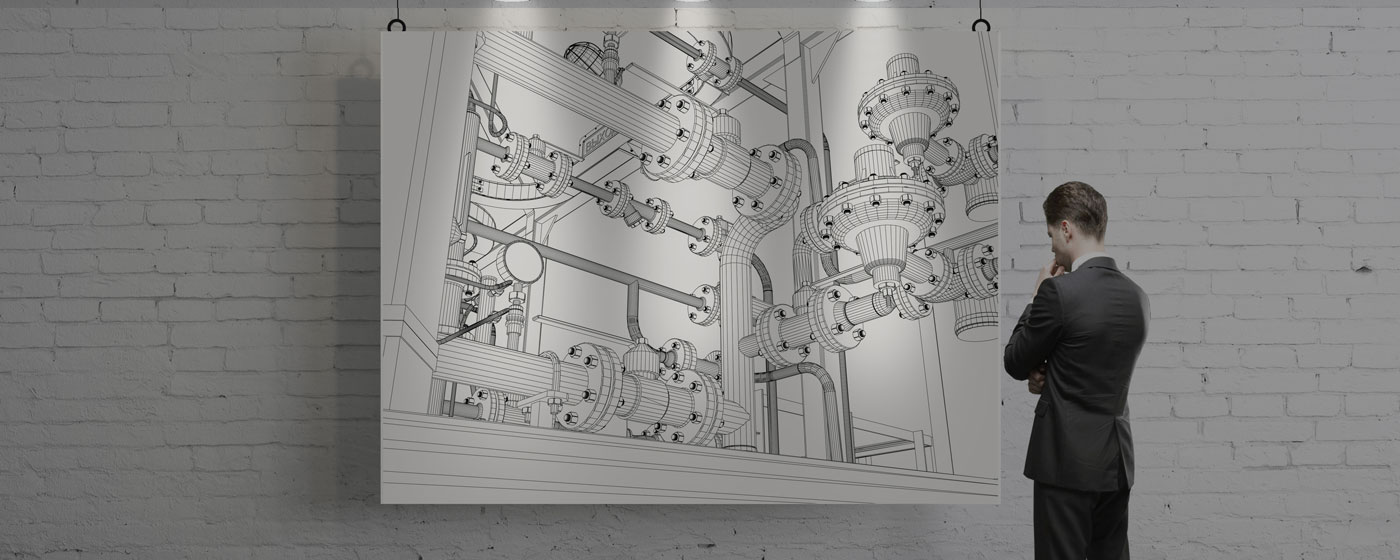

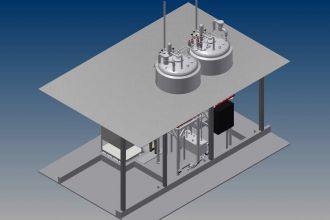

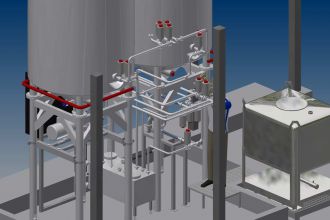

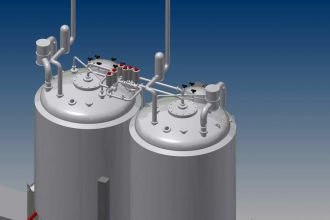

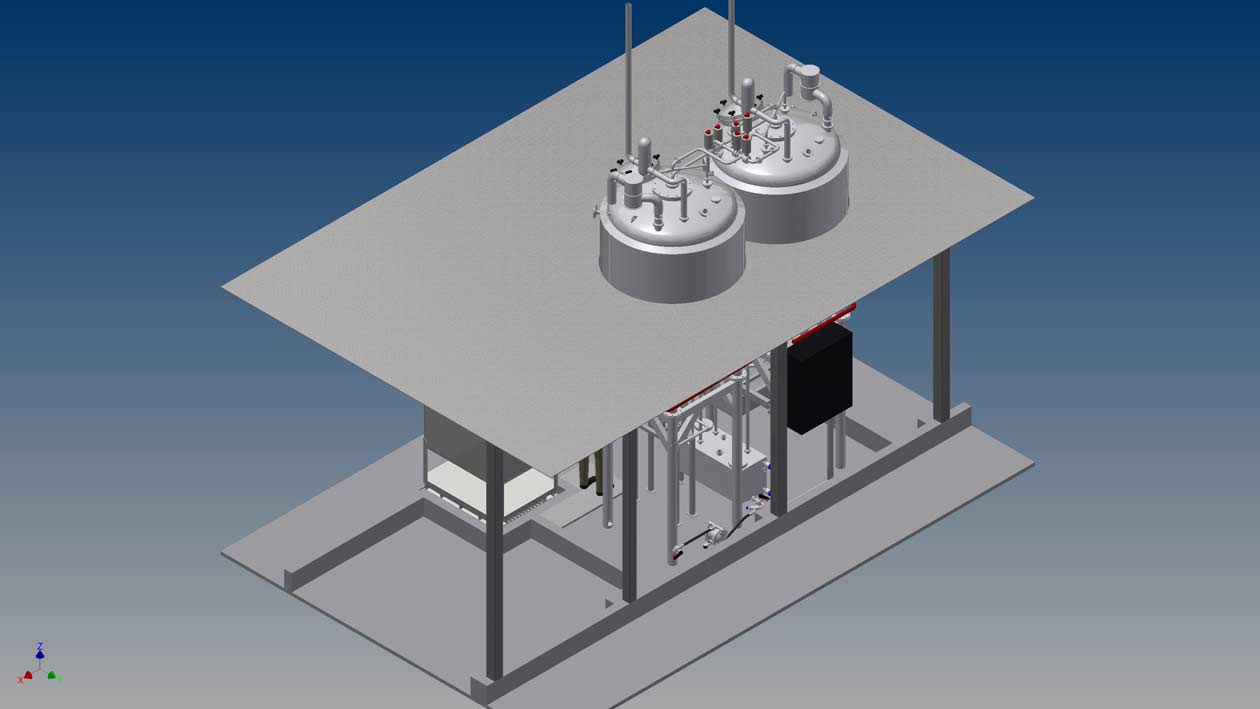

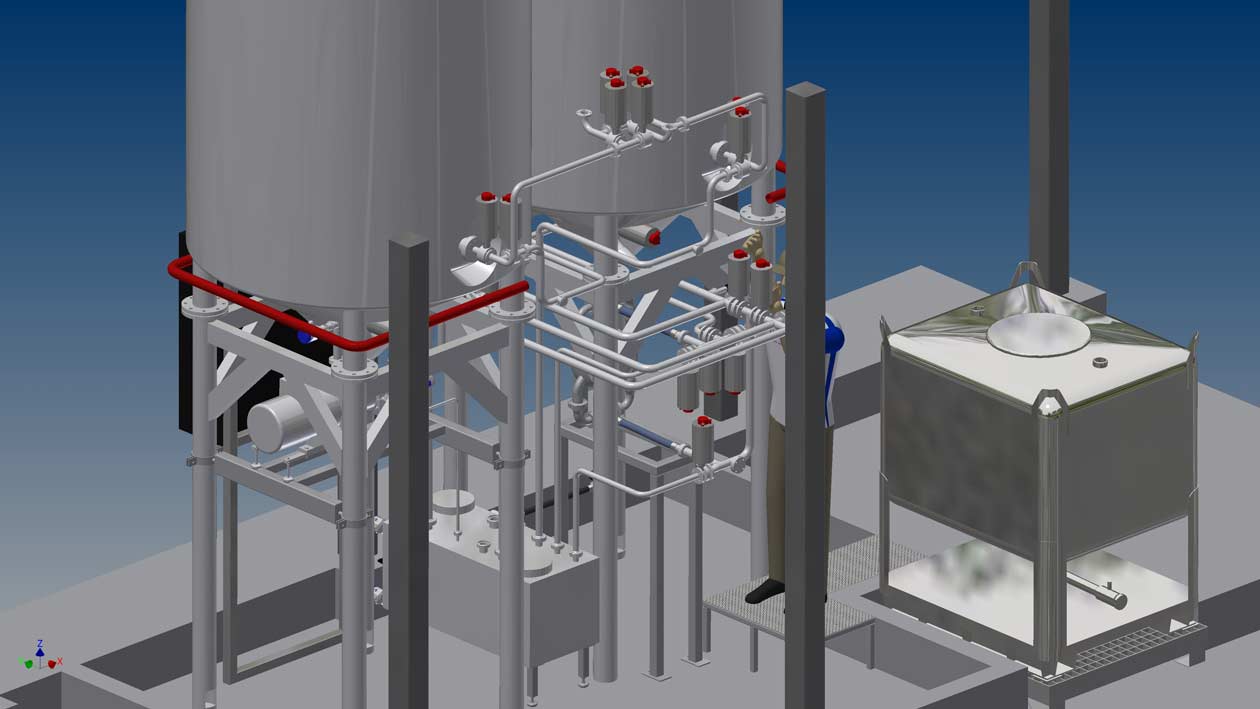

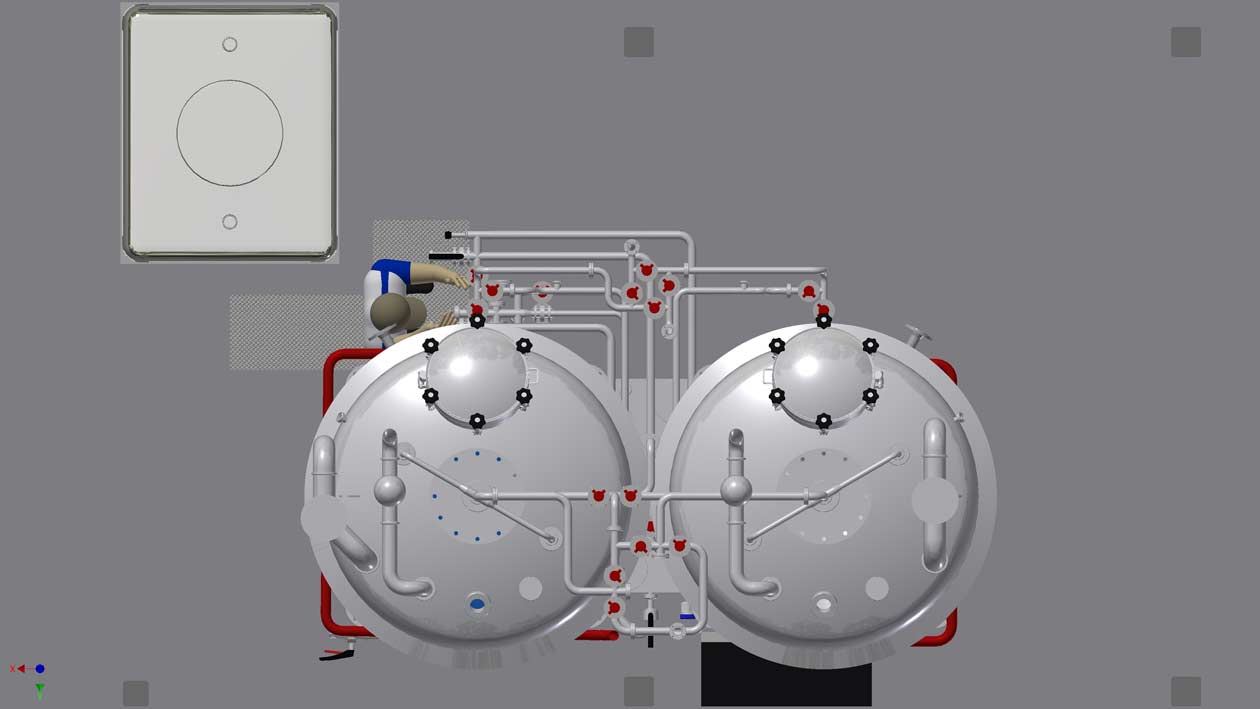

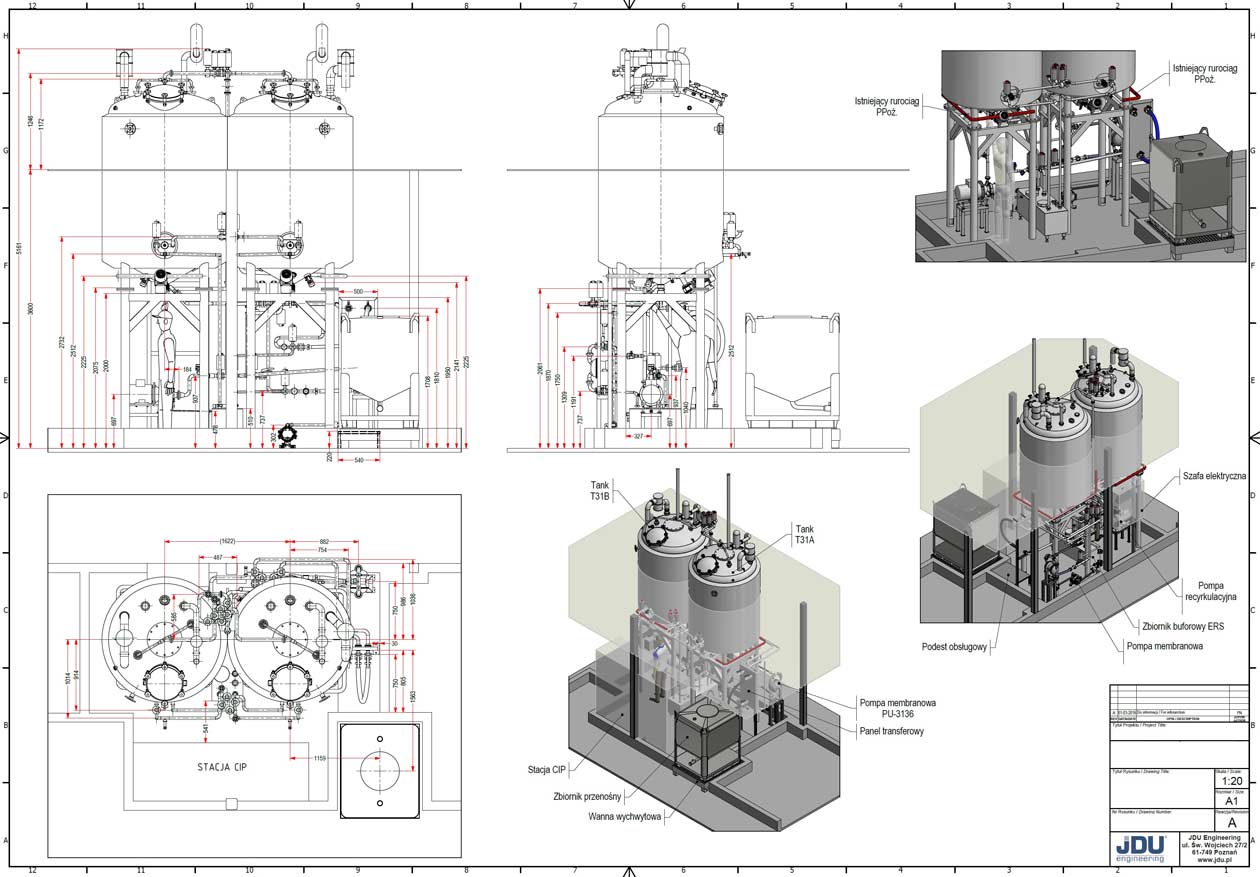

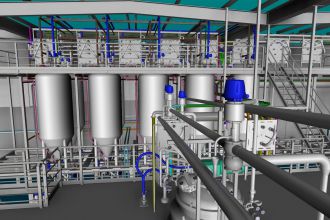

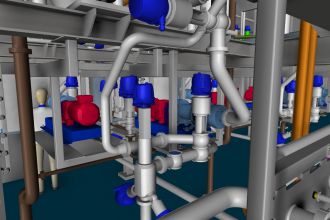

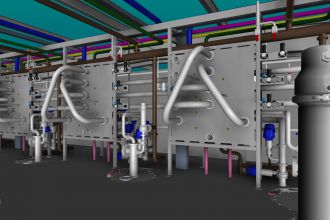

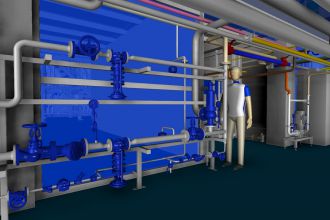

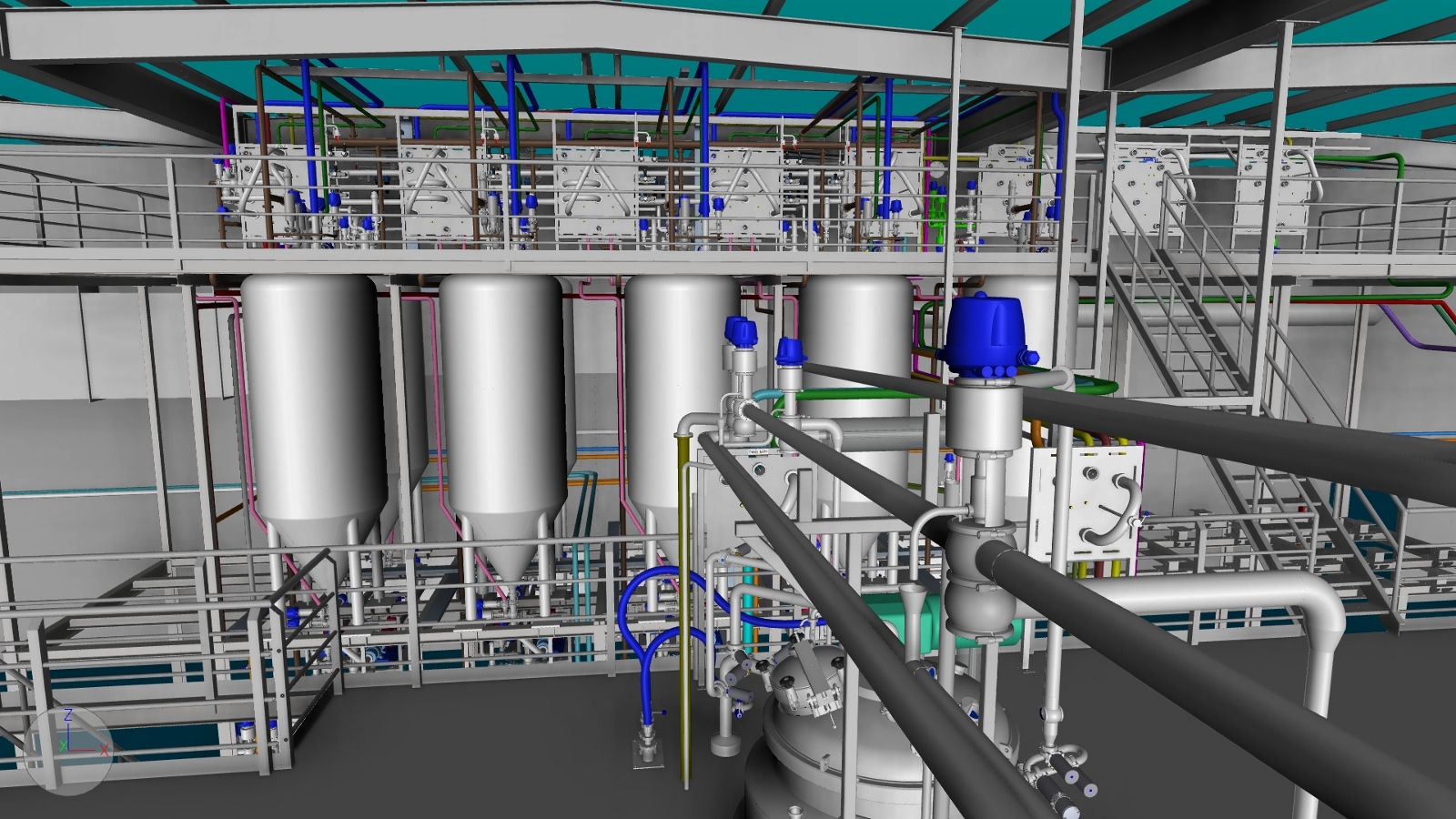

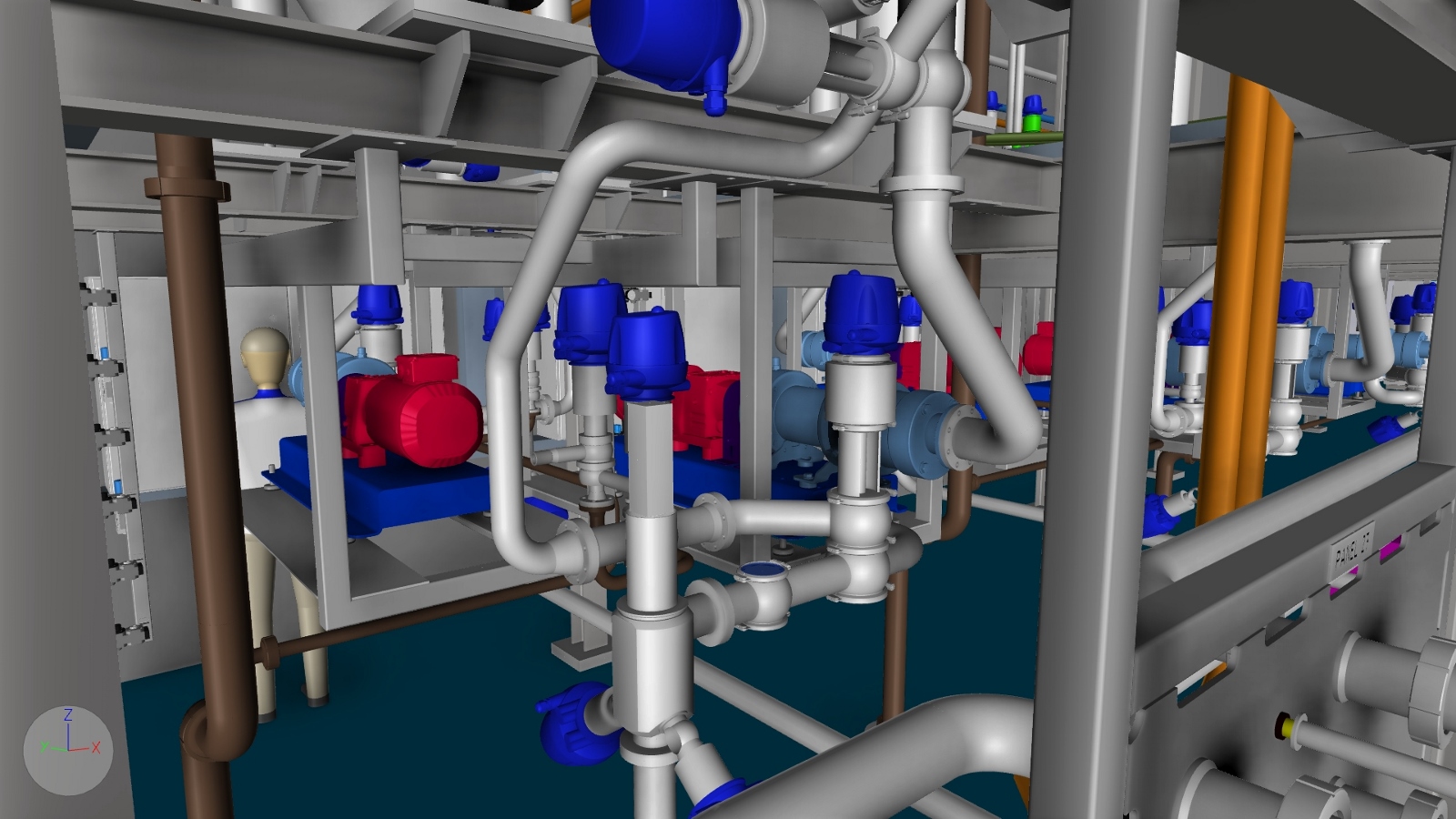

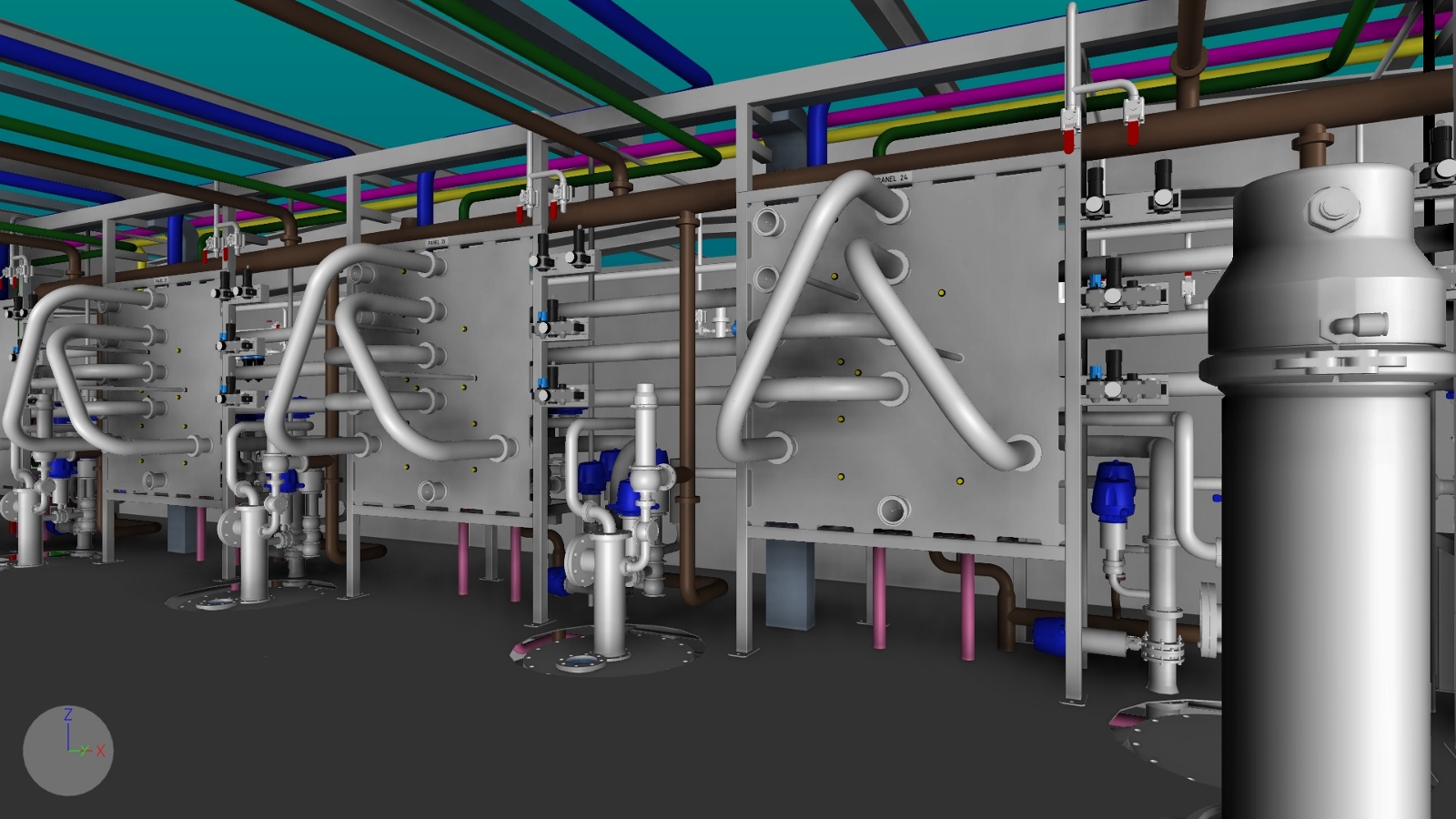

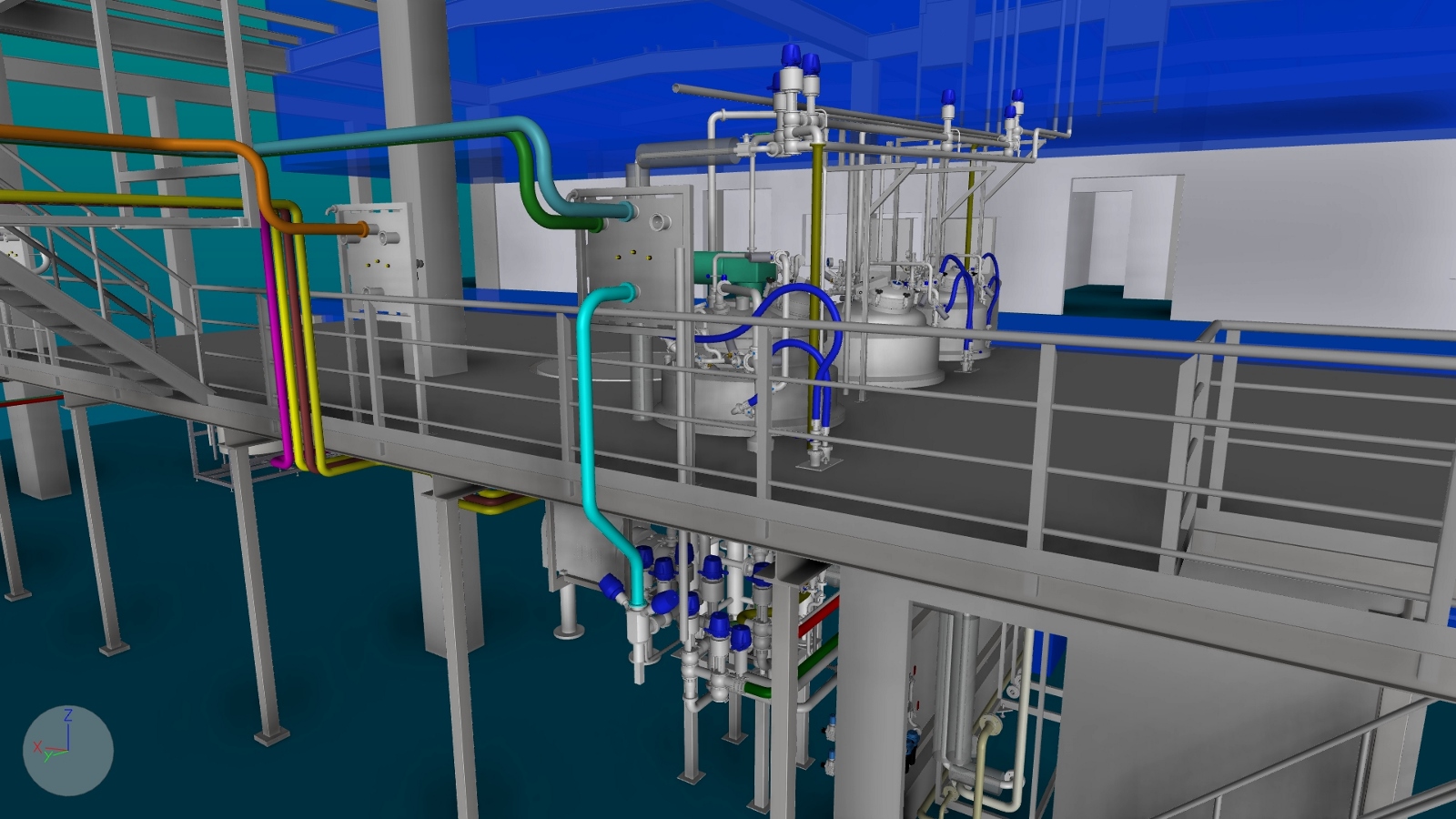

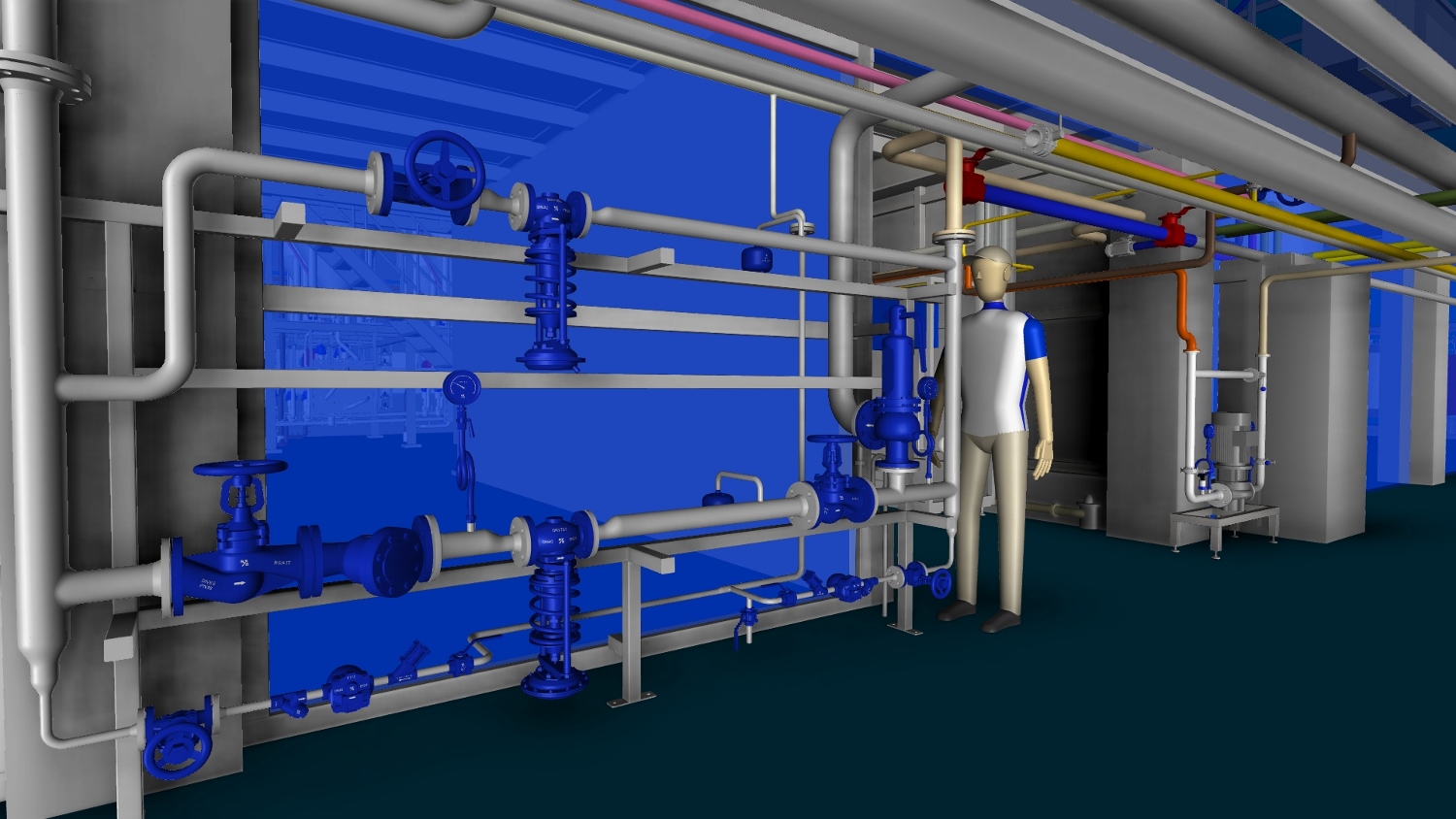

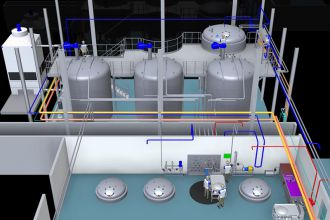

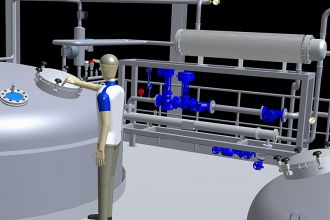

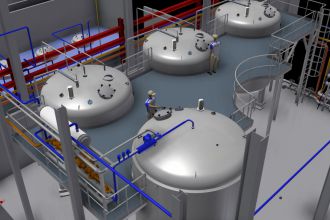

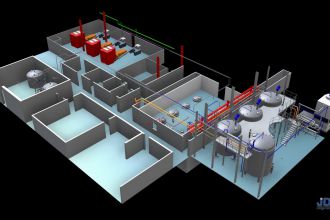

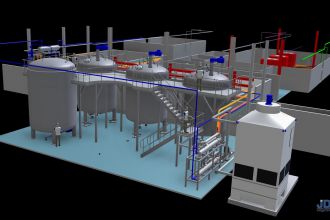

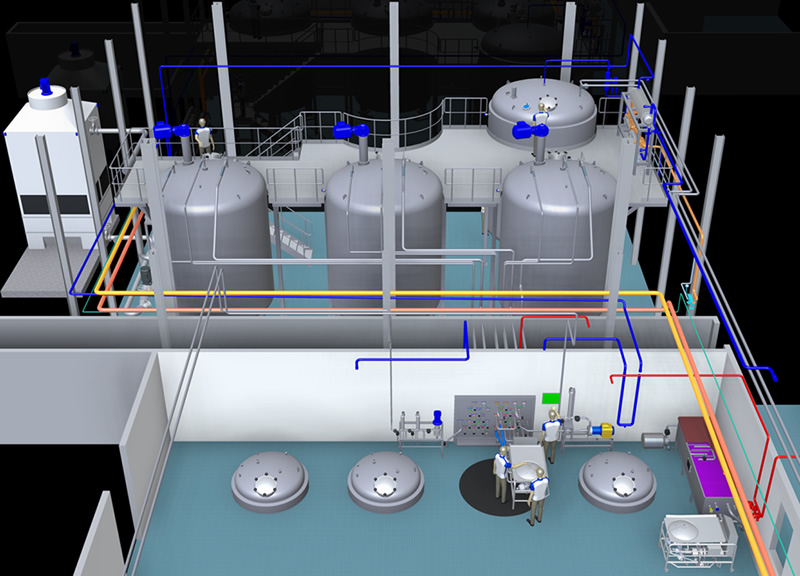

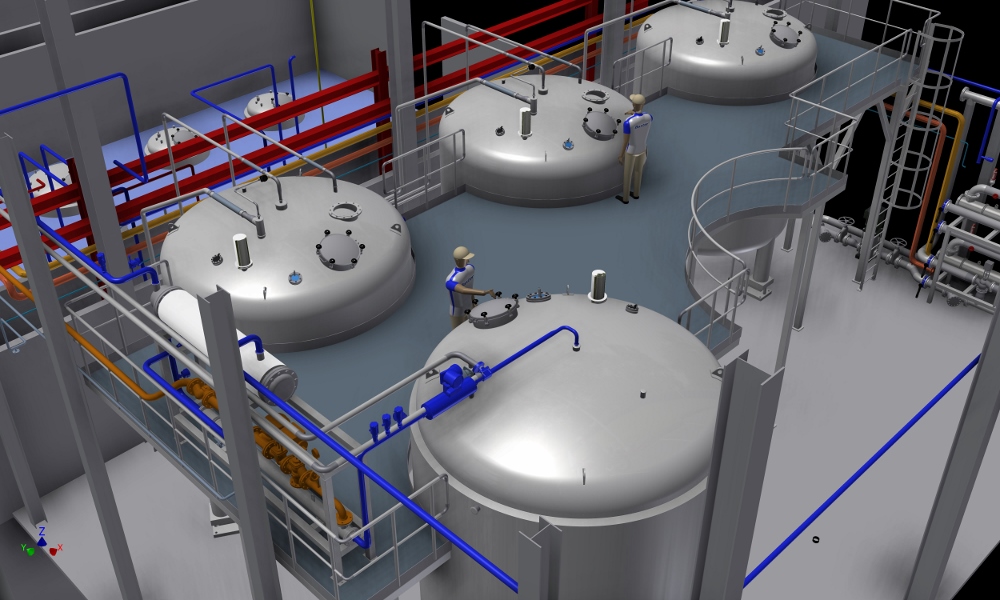

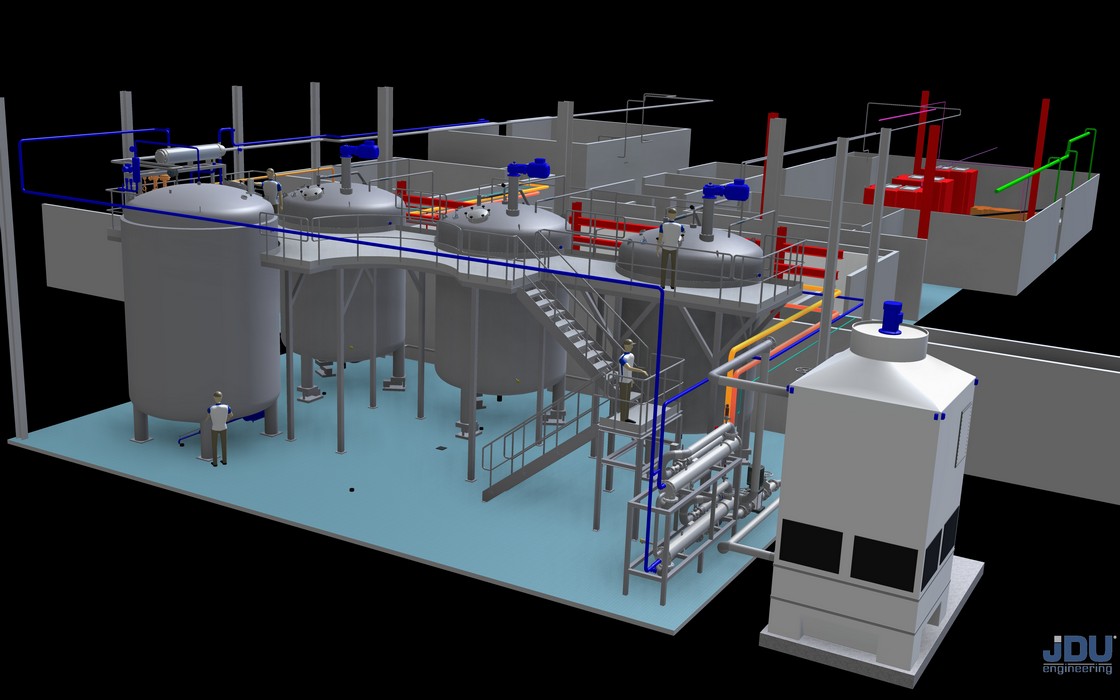

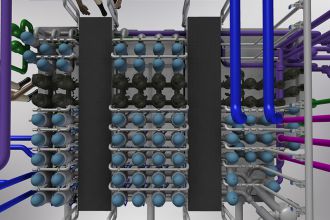

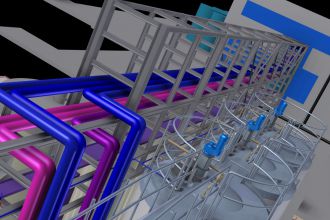

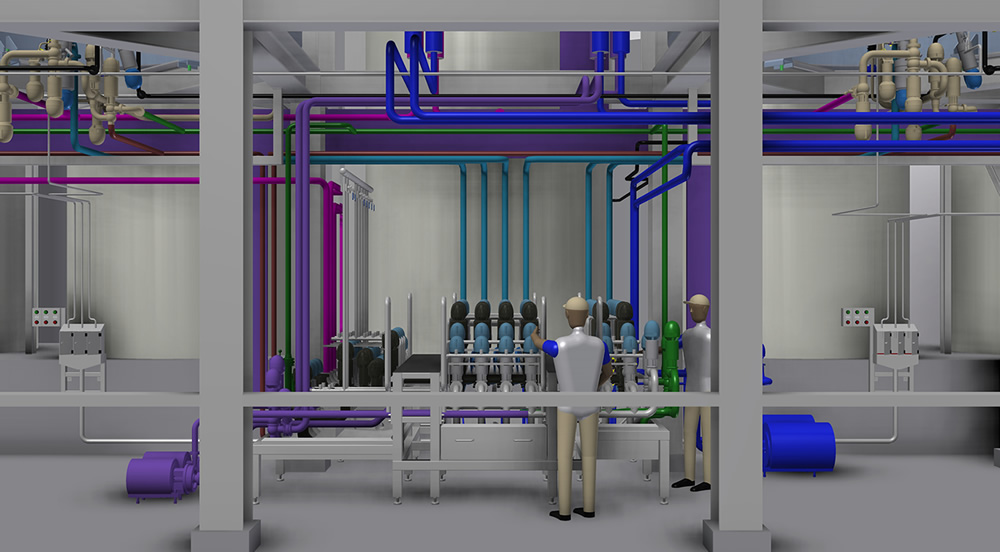

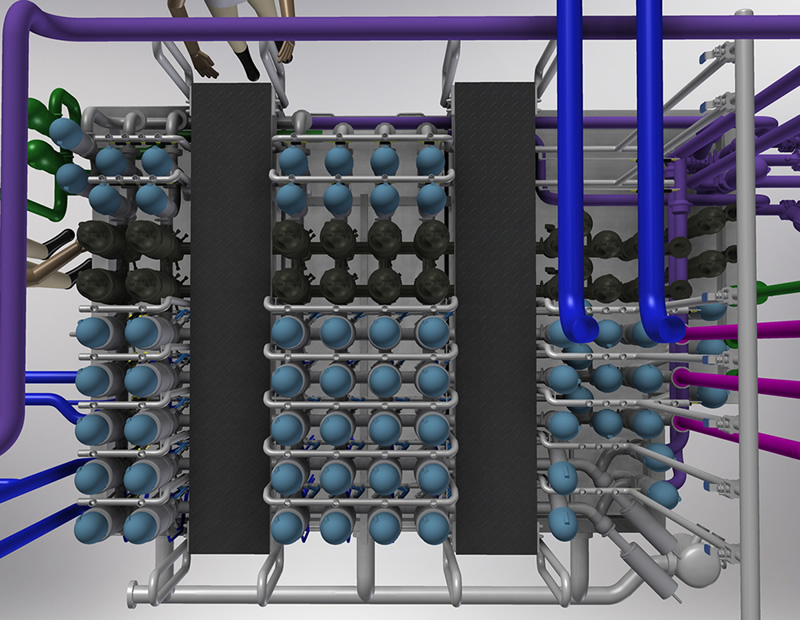

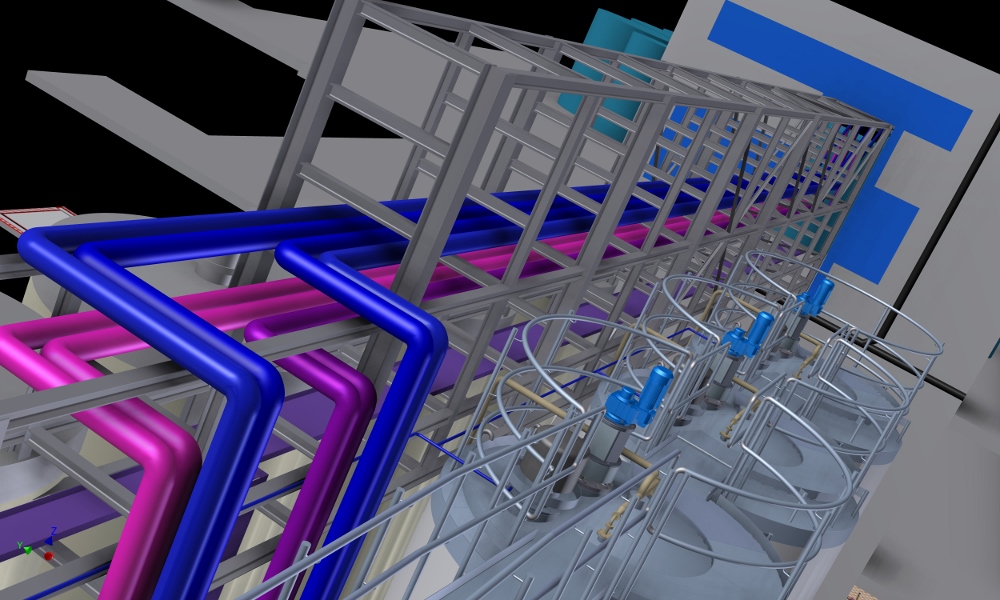

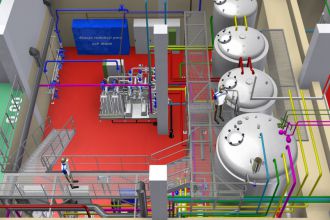

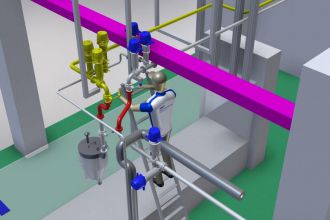

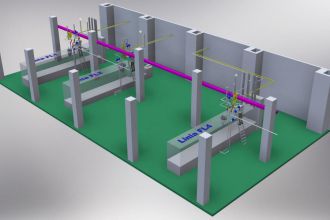

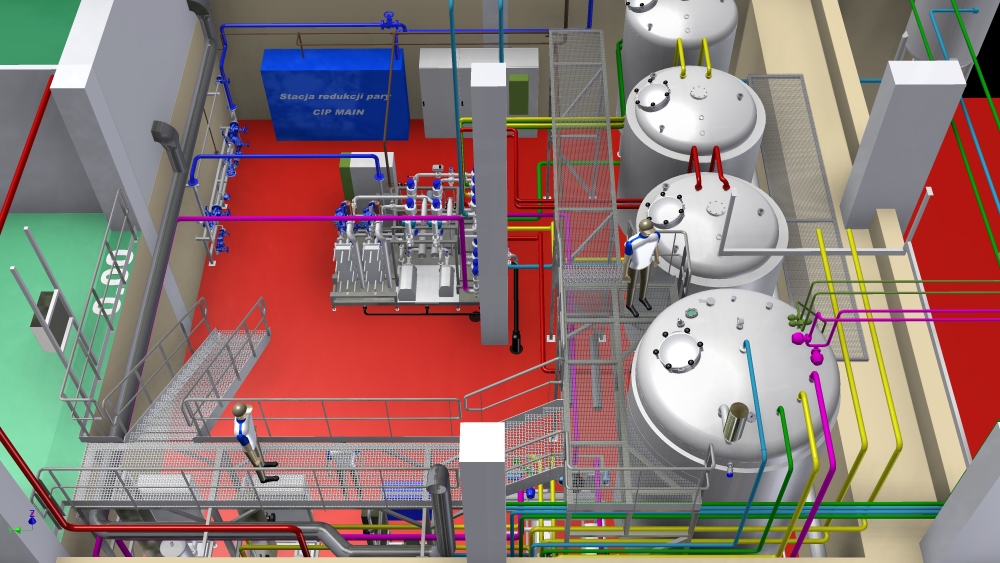

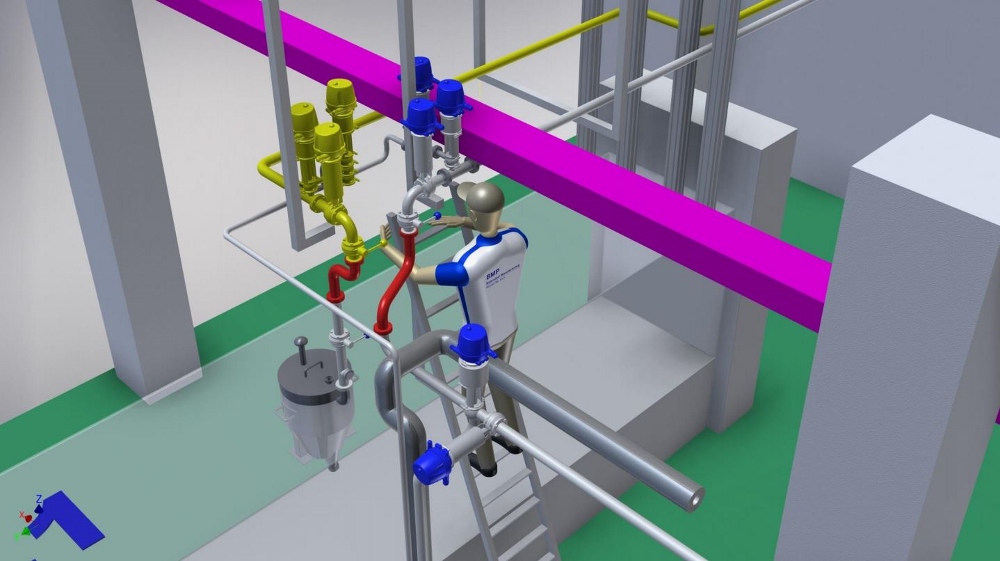

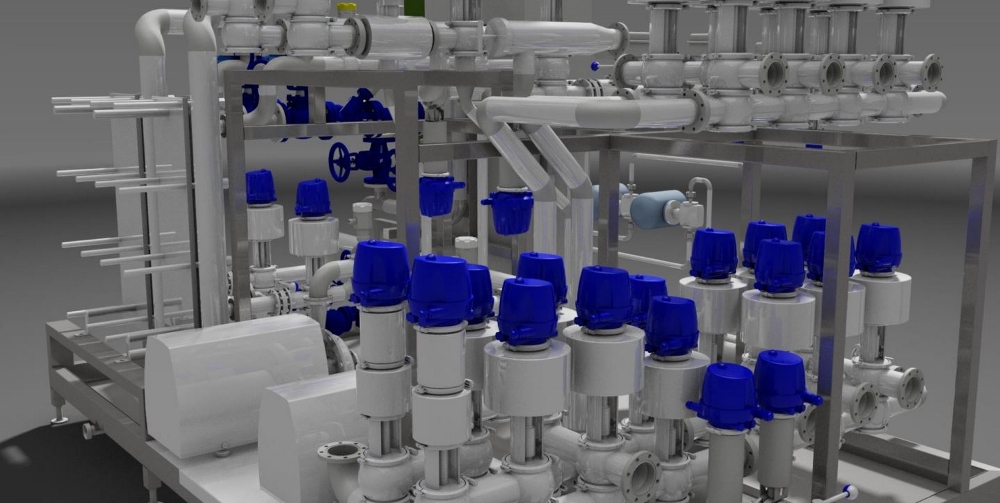

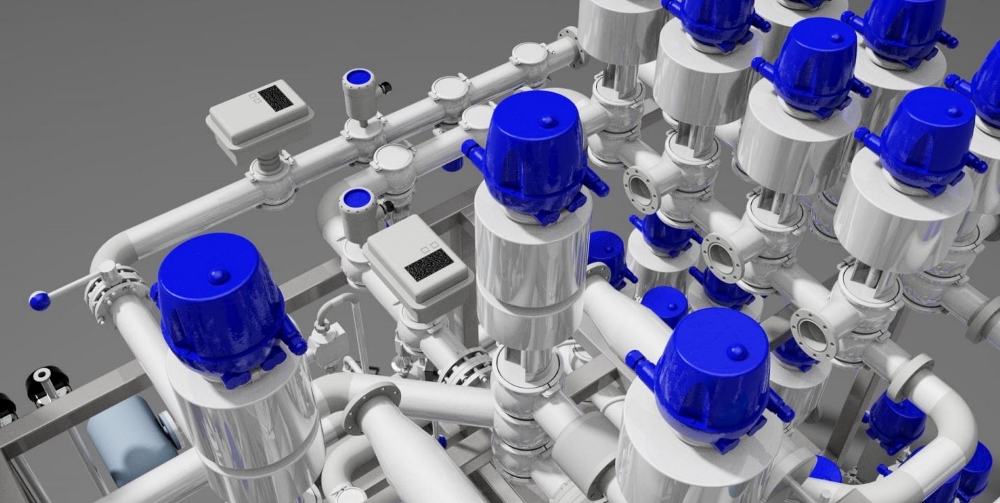

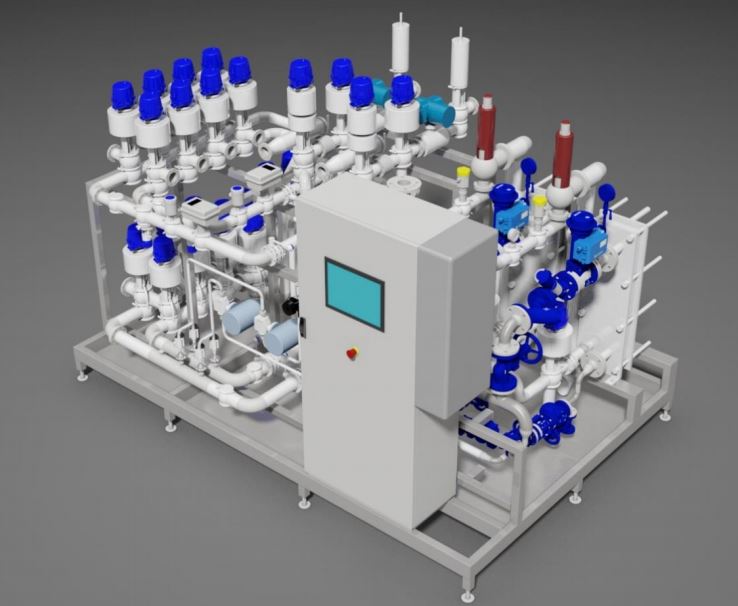

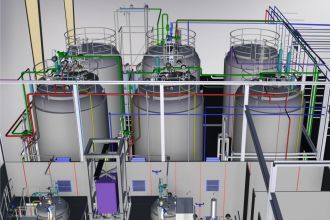

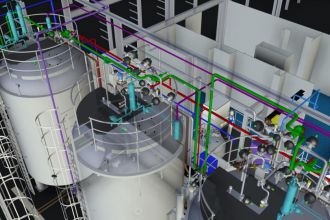

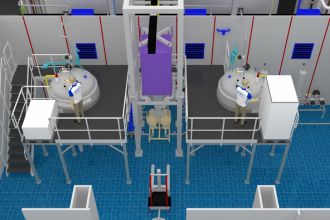

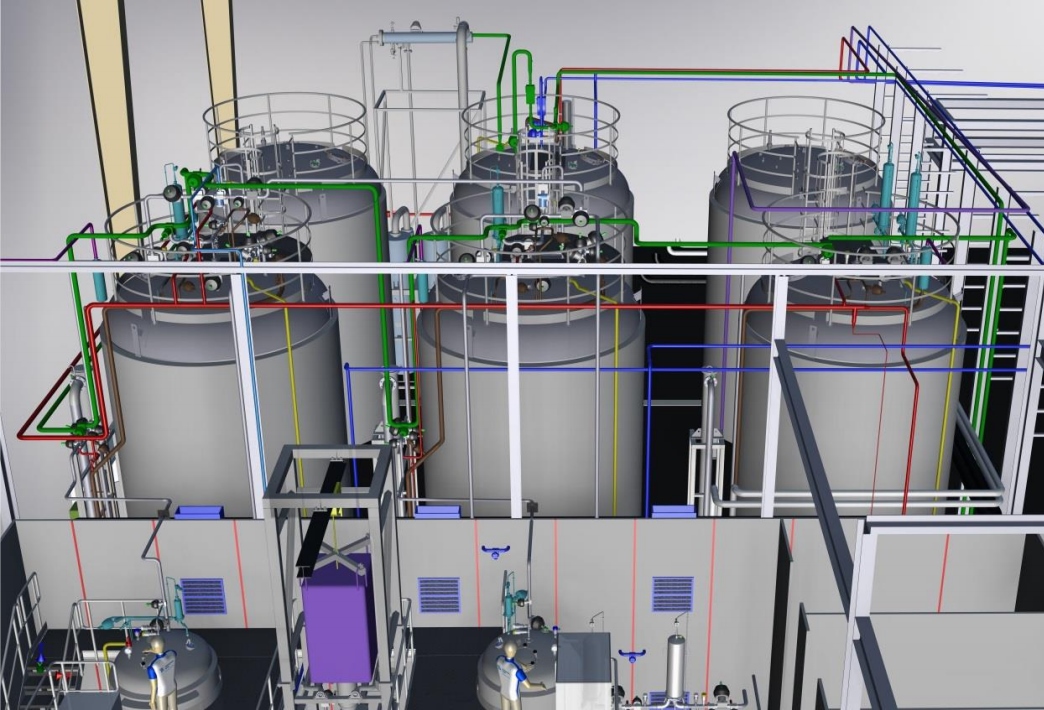

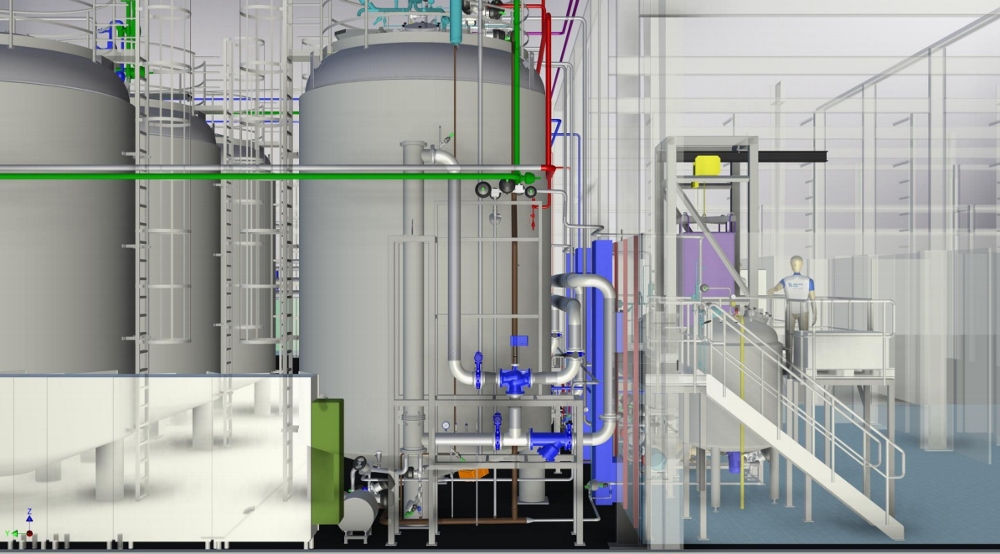

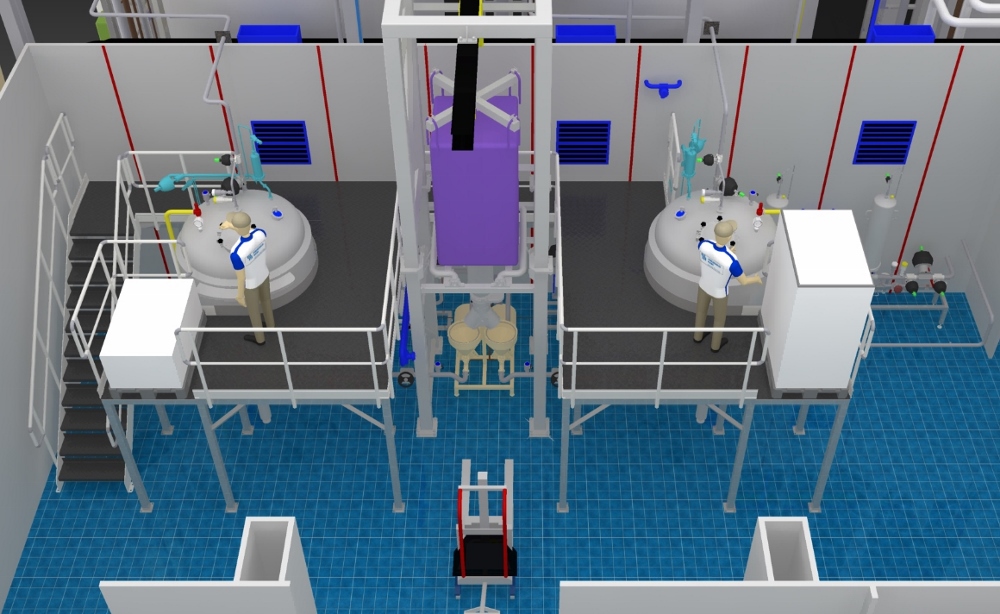

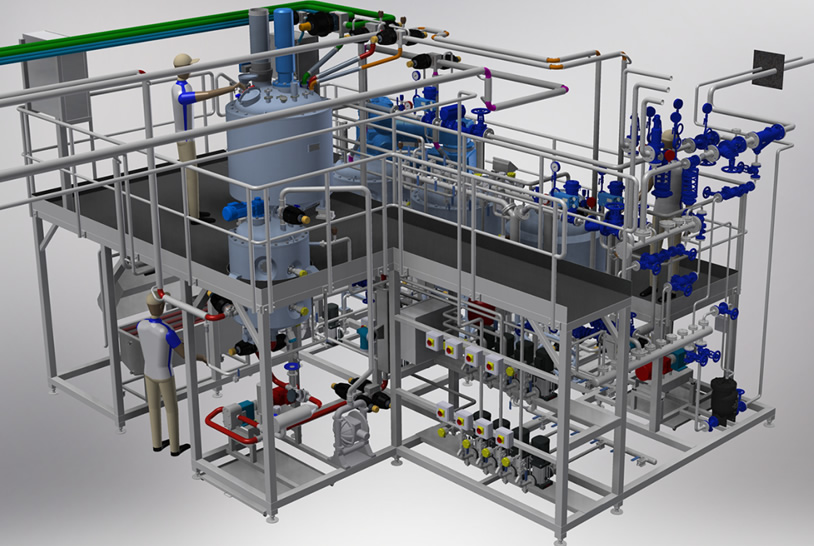

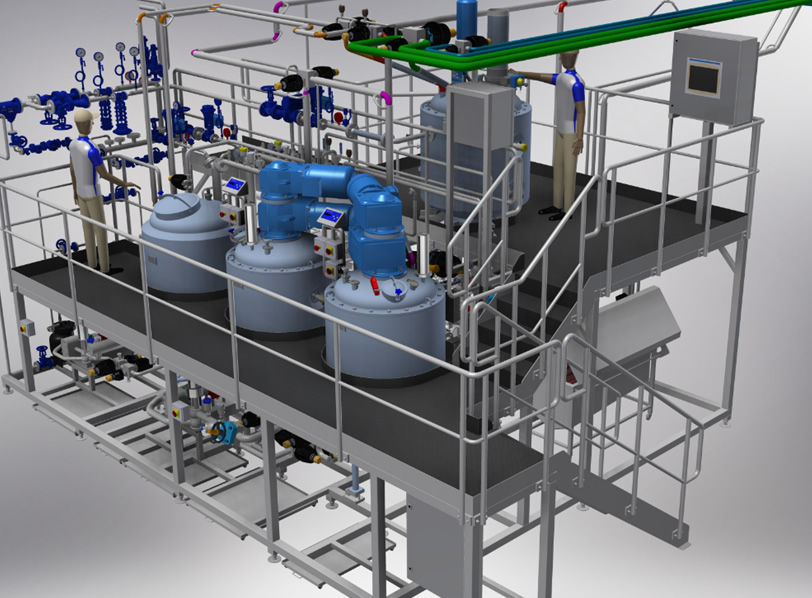

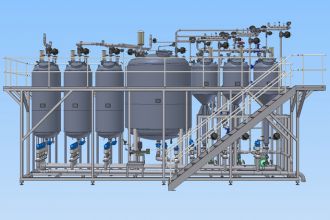

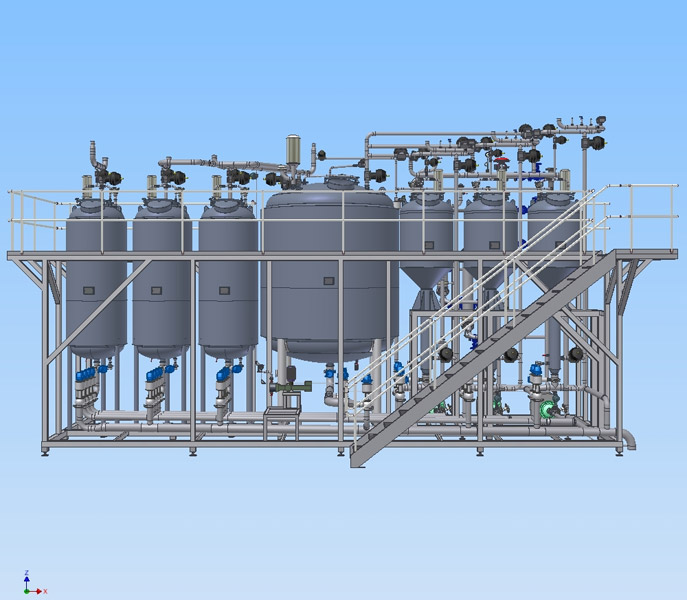

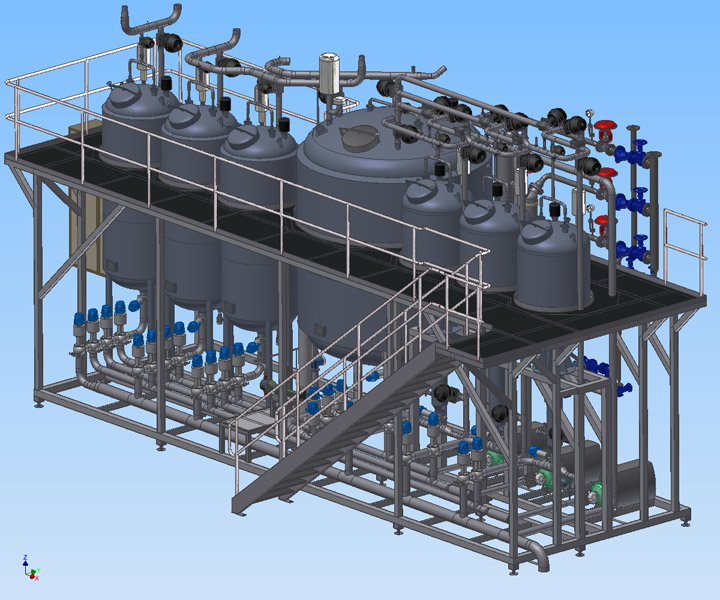

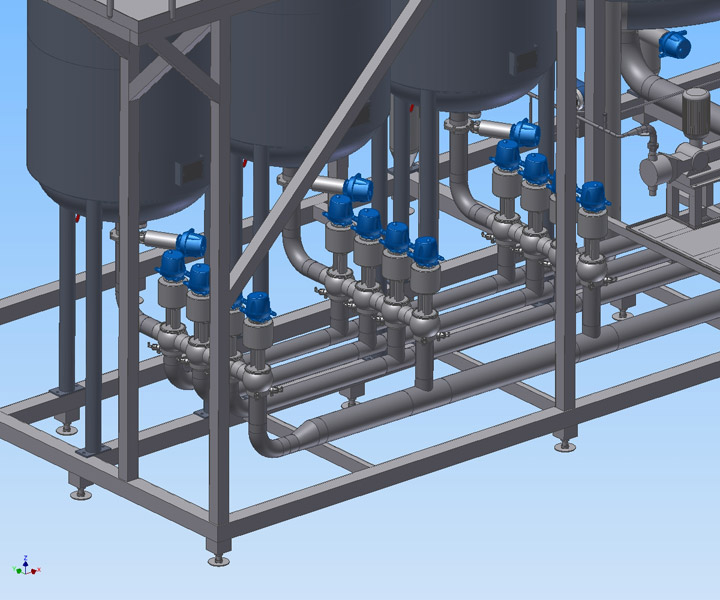

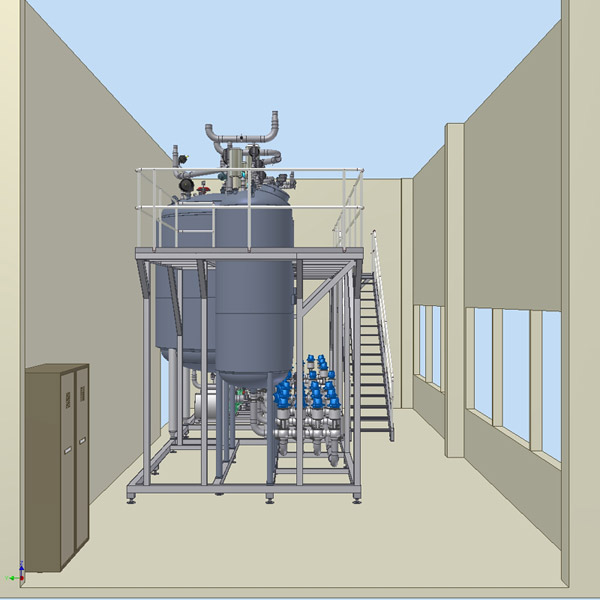

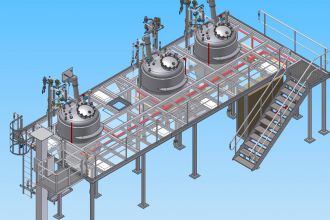

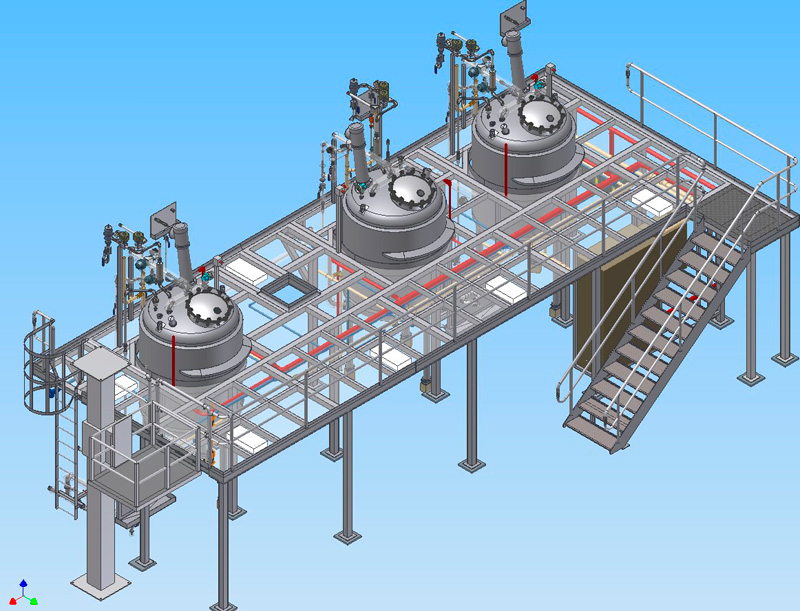

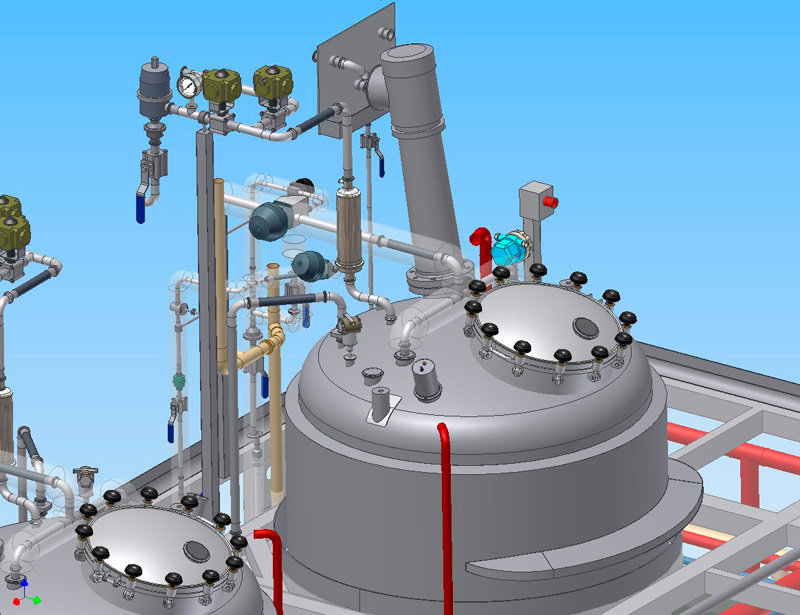

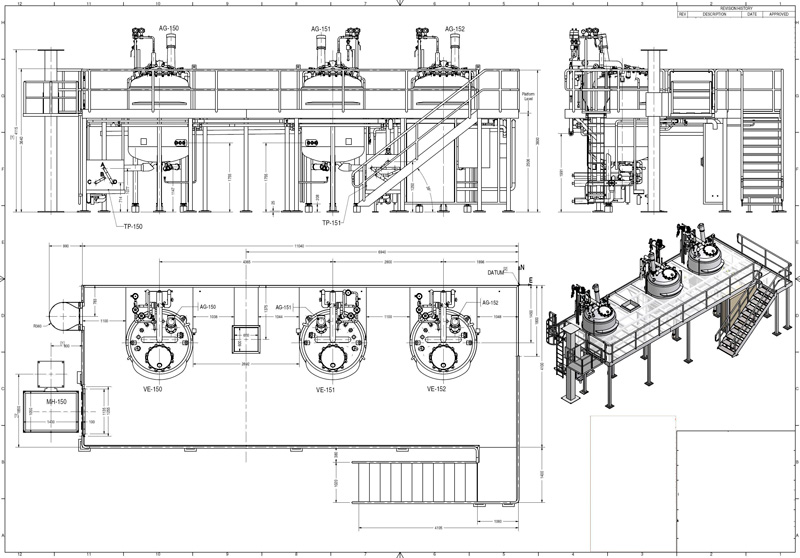

- 3D models of facilities and installations showing the location of all devices, pipelines and valves,

- Implementation and assembly documentation for tanks, pipelines, modular systems,

- Performing author's supervision and / or investor supervision during the construction and assembly,

- Technical consulting,

Several of our projects are presented below: